Welcome to Dongguan Jixuan Electronic Materials Co., Ltd.!

Dongguan Jixuan Electronic Materials Co., Ltd.

Details

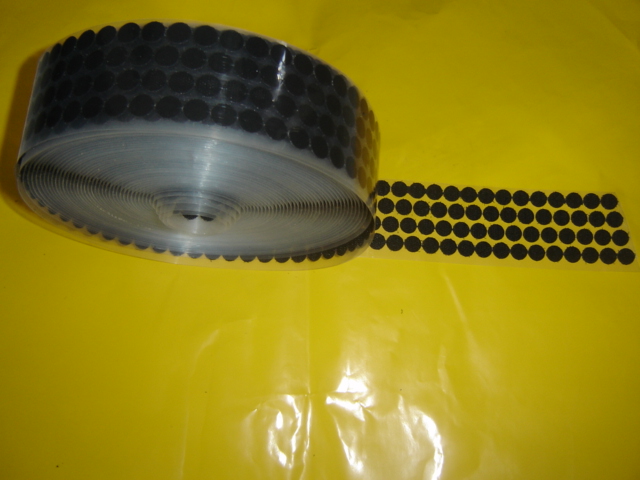

Product introduction: Punch-type adhesive-backed Velcro refers to the base of ordinary Velcro and special Velcro tape itself, through a high-temperature self-adhesive hot-melting machine, the glue is melted on the back of the ordinary Velcro and special Velcro tapes, and then pasted. The upper layer of oily release paper is the finished adhesive Velcro.

Adhesive Velcro classification:

1. There are ordinary hot-melt glues in the Velcro, which has a low melting point and is suitable for use in low temperature environments and winter.

2. The other is high temperature resistant hot melt adhesive, which has a high melting point and is suitable for use in summer and some high temperature machinery. It has strong adhesion and strong holding power after adhesion.

3. There is also a 3M self-adhesive product, which is a relatively special high-end processed product that is cut into the corresponding specifications and adhered to the back of the Velcro product by using 3M glue!

Adhesive process:

The adhesive Velcro machine can process ordinary adhesive backing, and can also process back-to-back lamination.

Ordinary back glue processing can process back glue with specifications between 12.5-200mm wide, and ordinary back glue processing can process the following materials; ordinary Velcro back glue, plastic hook back glue, flannel back glue, etc.

The materials for back-to-back processing can be: ordinary hook and paste flannel processing, plastic hook and paste flannel processing, ordinary hook and paste ordinary wool processing, etc.

The release paper of the self-adhesive Velcro is generally white, and less commonly used is yellow paper, transparent color paper, milky white paper, etc.

Sliced square-backed Velcro: Generally, white paper has thickening and ordinary thickness. The commonly used release paper is ordinary thickness. If you do not say what kind of paper you use during production, the general production staff will automatically use it for you. Normal thickness.

Adhesive Velcro classification:

1. There are ordinary hot-melt glues in the Velcro, which has a low melting point and is suitable for use in low temperature environments and winter.

2. The other is high temperature resistant hot melt adhesive, which has a high melting point and is suitable for use in summer and some high temperature machinery. It has strong adhesion and strong holding power after adhesion.

3. There is also a 3M self-adhesive product, which is a relatively special high-end processed product that is cut into the corresponding specifications and adhered to the back of the Velcro product by using 3M glue!

Adhesive process:

The adhesive Velcro machine can process ordinary adhesive backing, and can also process back-to-back lamination.

Ordinary back glue processing can process back glue with specifications between 12.5-200mm wide, and ordinary back glue processing can process the following materials; ordinary Velcro back glue, plastic hook back glue, flannel back glue, etc.

The materials for back-to-back processing can be: ordinary hook and paste flannel processing, plastic hook and paste flannel processing, ordinary hook and paste ordinary wool processing, etc.

The release paper of the self-adhesive Velcro is generally white, and less commonly used is yellow paper, transparent color paper, milky white paper, etc.

Sliced square-backed Velcro: Generally, white paper has thickening and ordinary thickness. The commonly used release paper is ordinary thickness. If you do not say what kind of paper you use during production, the general production staff will automatically use it for you. Normal thickness.